The main applications of Onda brazed plate heat exchangers is for the evaporation and condensation of refrigerant gas in air-conditioning and refrigeration plants, the hot water production in heat pumps and heat recovery. Onda's brazed plate heat exchangers are compatible with all modern refrigerants.

Only top quality materials are used in the manufacture the ONDA brazed plate heat exchangers. The Plate heat exchangers are made from Stainless steel thickness 0.0138” (316L type), the connections are also Stainless steel (304L type) and the brazing material is copper.

Afcon is the sole importer of Onda Brazed Plate Heat Exchangers in South Africa. Contact our heat exchanger department - Afcool Heat Exchangers

Afcon's stand at the SAIRAC GOLF Day

The SAIRAC Golf Day held on Friday 8th September, was the usual success and very well supported by the industry, with a record field of 38 four balls. Thank you to Tarryn Ching for her exceptional organisation. As always it is fantastic to meet our fellow HVAC&R colleagues in a relaxed atmosphere.

For the third year running Afcon sponsored the 11th hole. We thank all of you who visited our hole, and are certain the banter and cheer experienced cannot have been rivalled by any other. It was a glorious day out on the course in sunny Durban. Our congratulations to the winners of the day and to the Airconditioning Project's four ball who won the SAIRAC trophy.

To view the images bigger please click on each image. Our marketing team would love to hear your feedback on our new newsletter format.

Afcon Customer Profile - Craig Scott

This week we sat down with Craig Scott, of CS Air, to chat about where he started, where he is now, and everything in between.

Craig has been in the HVAC industry for 25 years, and first entered it at Republic Refrigeration and Airco, where his interest was sparked and he began his apprenticeship. Craig went on to work for Republic Refrigeration and Airco for two years thereafter, before moving to ACS, Air-conditioning and Pump Installations, where he worked for the next 10 years.

In 1999 Craig opened his own company and CS Air was born. Over the respective 18 years CS Air has worked on many exciting projects, and found it’s specialty in central plants particularly chilled water plants.

A current example of an exciting project that CS Air is working on, is the systems installation for the new Cornubia Virgin Active. Virgin Active has been a client of CS Air for nearly 25 years, and CS Air has been involved in the majority of Natal’s Virgin Active installations. Another project that CS Air has been able to “sink their teeth into” of late, is the new Sibaya Dunes development, which involves the installation of large Samsung VRV systems in the presidential apartments.

Craig is very passionate about what he does, and he states that his passion comes from his love of the challenge the HVAC industry provides. One of the major challenges of the industry is the technological advancements, which companies must keep abreast of. However Craig stated, that with the support of suppliers who bring in products that allow CS Air to provide the greatest efficiency and cost effectiveness to its clients, these challenges can be overcome.

Afcon Answers

What is the difference between Ethylene Glycol and Propylene Glycol?

What You Need To Know

Both ethylene glycol and propylene glycol solutions will effectively lower the freezing point of water allowing it to be freely pumped through a variety of heat exchangers, and can be used interchangeably for most applications. While there are many minor variations in the properties between ethylene glycol and propylene glycol solutions, however there are two key differences that dictate which of the glycols is chosen for a particular application, namely toxicity and viscosity.

Toxicity

Ethylene glycol is more toxic than propylene glycol. About 2 - 4 ounces of ethylene glycol can be fatal if ingested by an adult human. Whereas, propylene glycol is a food additive and is not harmful to humans if ingested in moderate amounts. Therefore, propylene glycol solutions are preferred for many applications, particularly when human exposure can occur.

Viscosity

While differences in viscosity between ethylene glycol solutions and propylene glycol solutions at elevated temperatures are minimal, at temperatures below -18C the viscosity differences become significant. If heat transfer at these low temperatures is required, ethylene glycol solutions should be used. In addition, ethylene glycol solutions will require less pumping horsepower under cold conditions. If these liquid characteristics are important, ethylene glycol is usually chosen for the application.

Why you need Major Tech Tools today

What is “Dew Point”?

Which fouling factors are suggested for the selection of shell and tube heat exchangers?

The fouling factor is important for the selection of an evaporator. The values suggested to input in selection software are:

For evaporators:

- Normal water in closed circuit: 0,000043 m2K/W;

- Water in open circuit: 0,000086 m2K/W;

- Solutions with glycol <40%: 0,000086 m2K/W;

- Solutions with glycol >40%: 0,000172 m2K/W.

For condensers:

- Normal city water: 0,000043 m2K/W;

- Treated tower water: 0,000043 m2K/W;

- River water: 0,000086 m2K/W;

- Solutions with glycol <40%: 0,000086 m2K/W;

- Solutions with glycol >40%: 0,000172 m2K/W.

Contact our heat exchanger department - Afcool Heat Exchangers

Eberle AC Controls

Eberle is a leading European brand that manufactures energy efficient residential and commercial heating and air-conditioning controls. Eberle has over 80 years of experience and prides itself on reliability, quality, technical excellence and sustainable production.

Afcon holds a wide range of, reasonably priced, Eberle controls. This range includes controls with dual heating and cooling options as well as single function controls. We also offer the choice of LED indicators and models with proportional outputs for heating and cooling.

For more information on Eberle AC Controls, and controls technical specifications, click here . . .

GOING GREEN IS COOL

This phase down is being achieved through the introduction of quota allocations and sectorial bans on high-GWP HFCs as well as multiple governments taking further steps to reduce the use of refrigerants with a substantial impact on the environment.

Bitzer has expanded their range of compressors to meet this need for environmentally sustainable refrigeration. The Bitzer Ammonia Compressor Pack (ACP) does just that. Bitzer’s ACP is designed for a wide range of operations in high, mid and low temperature applications in industrial refrigeration and process cooling.

Technical specifications

- Available with a capacity range of 100 to 450 TR

- Modular compressors units comprise up to 3 compressors

- Compressor packs can be connected (up to 9 compressors) and connected to a single controller

- Equipped with frequency inverter

- Common oil separator

Advantages

- Optimal part load performance

- High efficiency: individual compressors can be turned on and off depending on requirements

- Maximum redundancy for high operating reliability: system has multiple ammonia screw compressors which increases its reliability over single industrial compressors

- Bitzer advanced oil management system

- Reduced installation costs

- Durability

- Fast availability for all replacement parts

For more infoamtion . . .

What does “Approach” mean in heat exchangers?

Bitzer Compressors and Ammonia Seminar

Following the success of last year’s Roadshow Bitzer South Africa offered another Road Show event in Durban yesterday, covering Bitzer compressors and Ammonia applications.

The event was held at the Durban Country Club. And was a great success. Thank you to all who attended, and to Bitzer South Africa for hosting.

If you are interested in the information discussed at this seminar . . .

What is “Bubble Point”?

The bubble point is the temperature at which a liquid forms bubbles (usually the lowest boiling point of one of the constituents of a mixture like R407C).

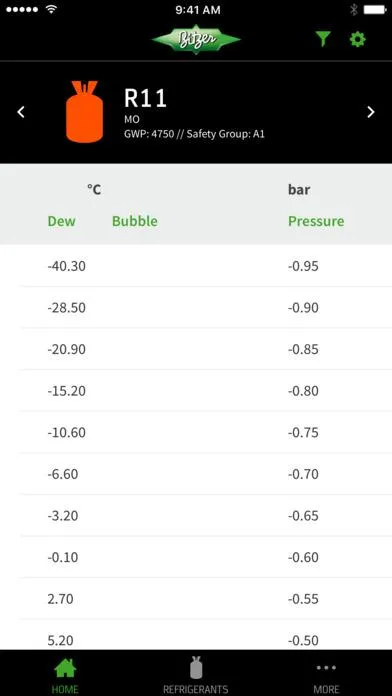

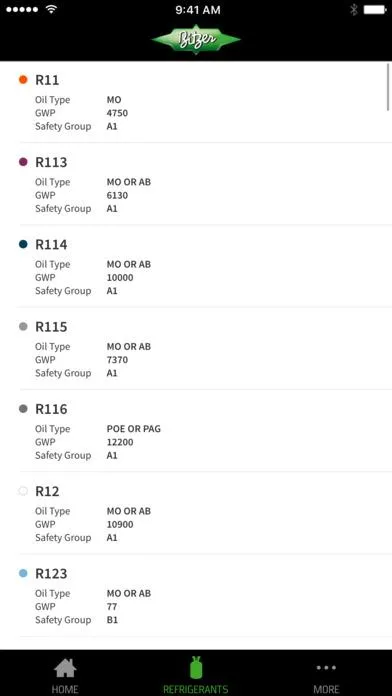

BITZER REFRIGERANT RULER

By BITZER

Description

The BITZER REFRIGERANT RULER Work out refrigerant data – quickly and easily – with the free BITZER REFRIGERANT RULER from BITZER. The BITZER REFRIGERANT RULER, developed for iOS, covers all of the common refrigerants and contains data on their relevant physical properties. It offers an intuitive user interface with which it is quite simple to work out temperature and pressure for various refrigerants. The tool is one of the few applications which enables the use of imperial and metric units at the same time. It is available in both English and German. The main functions On the start screen, the user is shown all of the relevant information about the selected refrigerant, such as its dew and bubble point depending upon the pressure, as well as information about the best type of oil to use, the refrigerant’s global warming potential (GWP value) and its safety group. A ‘Refrigerants’ menu at the top-left edge of the screen gives you an overview of all available refrigerants as a list. When you select a refrigerant from the list, you are then shown its details page which contains more valuable information. By swiping to the right or left on the start screen, you can also switch directly to another refrigerant. Settings and filter functions can be found at the top right. The filter functions make it possible to restrict the refrigerants shown by their GWP values or to just show natural refrigerants. The settings allow you to switch between metric and imperial units. Additional advantages of the BITZER REFRIGERANT RULER The extra functions to select for natural refrigerants and for GWP values are two new and convenient options. Moreover, you can also access BITZER’s latest refrigerant report directly from the app!

https://play.google.com/store/apps/details?id=com.bitzerus.refrigerant.ruler

https://itunes.apple.com/us/app/bitzer-refrigerant-ruler/id373683792?l=de&ls=1&mt=8

10′s of thousands of LPA® pumps have been installed as a simple retrofit means of getting liquid refrigerant to the expansion valves when minimum head pressure controls are set to reduced head pressures, thereby saving energy and increasing capacity at mild to cold outdoor temperatures.

The LPA® pump eliminates the usual problems of capacity loss and poor oil return due to operating with low head pressure.

Improved performance and efficiency of a system that has flash vapor in the liquid line. This is especially apparent if flash vapor is a serious problem, as in systems with excessive liquid line pressure drop, elevation gain in the liquid line, or if the air surrounding the liquid line is warmer than the outdoor temperature.

Reduced scaling problems on water-cooled systems when a small amount of high pressure liquid from the pump outlet is injected into the discharge line, reducing the vapour temperature.

The LPA works by boosting liquid refrigerant through the system…

The LPA works by boosting liquid refrigerant through the refrigeration system. By increasing the liquid’s pressure, the associated saturation temperature is raised, while the liquid temperature remains the same. The liquid becomes sub-cooled; reducing the potential for flashing prior to the expansion valve. With LPA, your business will enjoy higher efficiency, lower power draws and substantial cost savings.

Taken from: http://www.hysave.com/technology/lpa-systems/